HDPE Liner Pond: The Ultimate Solution for Your Water Retention Needs

In today's world, maintaining and preserving water resources is paramount. Ponds, whether for agricultural, industrial, or recreational purposes, play a crucial role in water retention. To ensure that your pond is efficient and environmentally friendly, the choice of the right liner is essential. In this article, we will explore the wonders of HDPE pond liners, their manufacturing process, and the benefits they offer.

Introduction

Ponds are essential for various purposes, from irrigation in agriculture to water containment in industrial applications. A critical component of an efficient pond is its liner, which prevents water seepage, controls water quality, and extends the pond's lifespan. Among the various liner materials available, HDPE (High-Density Polyethylene) pond liners stand out as a reliable and eco-friendly choice.

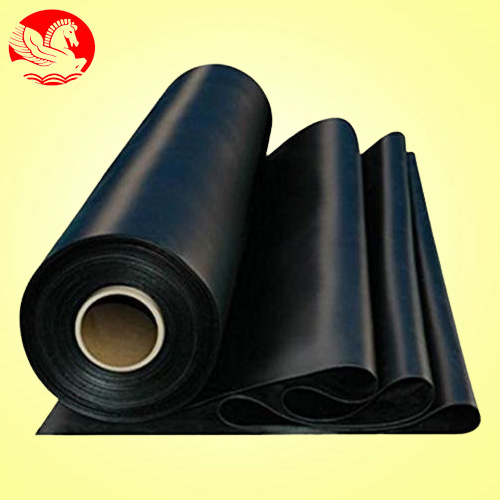

Understanding HDPE Liner

HDPE is a synthetic polymer known for its high strength, durability, and resistance to chemicals. These characteristics make it a perfect material for pond liners. HDPE pond liners are manufactured using a specialized process that ensures the utmost quality and reliability.

Advantages of HDPE Liners Pond

Durability

One of the key advantages of HDPE pond liners is their exceptional durability. They can withstand harsh weather conditions, resist punctures, and have a long lifespan, making them a cost-effective choice.

Chemical Resistance

HDPE liners are highly resistant to a wide range of chemicals, making them suitable for a variety of applications, including waste containment and water treatment.

Flexibility

HDPE liners are flexible, conforming to the pond's contours and minimizing the risk of leakage. Their flexibility also makes them easy to install.

Extrusion Process

The manufacturing of HDPE pond liners involves an extrusion process. It starts with the raw HDPE material being melted and extruded into a continuous sheet. This sheet is then rolled and cut to the desired size.

Quality Control

Quality control is a crucial step in HDPE liner manufacturing. Thorough testing ensures that the liners meet the necessary standards for strength and chemical resistance.

Applications of HDPE Liners

HDPE liners find application in a wide range of industries, including agriculture, aquaculture, and wastewater management. They are suitable for lining ponds, reservoirs, and lagoons.

Selecting the Right HDPE Pond Liner sheet

When choosing an HDPE pond liner, several factors must be considered, including:

Thickness

The thickness of the liner should match the specific requirements of your pond. Thicker liners offer greater durability and puncture resistance.

Size

Select a liner that comfortably fits the dimensions of your pond to minimize seams and potential weak points.

UV Resistance

For exposed ponds, UV-resistant HDPE liners are recommended to prevent degradation from sunlight exposure.

Installation of HDPE Liner

Proper installation is essential to maximize the benefits of HDPE liners. It involves site preparation and several installation steps to ensure a watertight seal.

Site Preparation

Site preparation includes clearing the area of debris and ensuring a smooth, compacted base.

Installation Steps

The installation process typically involves unrolling the liner, securing it in place, and welding seams for larger ponds.

Maintenance of HDPE Pond Liners

Regular inspection and maintenance are crucial to extending the life of your HDPE pond liner. Promptly address any damage or punctures to prevent leaks.

Cost Considerations

While the initial cost of HDPE liners may be higher than other materials, their long lifespan and durability make them a cost-effective choice in the long run.

Environmental Impact

HDPE liners are eco-friendly, as they are recyclable and do not release harmful substances into the environment. Choosing HDPE liners contributes to sustainability.

Comparing HDPE Liners to Other Materials

Comparing HDPE liners to alternatives like PVC and EPDM helps you make an informed choice based on your specific needs and budget.

Success Stories

Learn about real-world examples of how HDPE pond liners have benefitted various industries and applications.

FAQs About HDPE Pond Liners

1. Are HDPE pond liners safe for fish and aquatic life?

Yes, HDPE pond liners are safe for fish and aquatic life as they are chemical-resistant and do not release harmful substances.

2. Can HDPE liners be used for large reservoirs?

HDPE liners are suitable for both small and large ponds and reservoirs. Their durability and flexibility make them an excellent choice for various sizes.

3. How long can I expect an HDPE pond liner to last?

When properly maintained, HDPE pond liners can last for several decades.

4. Are HDPE pond liners easy to repair?

Yes, small punctures or damage to HDPE liners can be easily repaired using heat-welding techniques.

5. Is UV resistance important for all types of ponds?

UV resistance is essential for ponds that are exposed to direct sunlight. It prevents degradation and extends the liner's lifespan.

Conclusion

HDPE pond liners are the ultimate solution for water retention needs. Their durability, chemical resistance, and eco-friendly characteristics make them a top choice for a wide range of applications. By choosing HDPE liners, you can ensure the long-term success and environmental sustainability of your pond or reservoir.

.png)

Comments

Post a Comment